Why Lamination Matters More Than You Think

In commercial printing, surface lamination isn’t just decoration – it’s armor for your investment. As industry data shows:

Lamination applies micron-thin plastic film to prints, extending lifespan 3-5X.(Fogra Research 2023)

Whether you’re producing premium sticker labels, catalog covers, or product packaging, choosing between matte, gloss, or no lamination impacts:

Durability against scratches/moisture

Visual appeal and brand perception

Long-term replacement costs

The Matte Lamination Advantage

Science Behind the Finish: Microscopic silica particles create a light-diffusing surface

Key Benefits:

Professional Tactile Experience: Velvet-like texture signals luxury (ideal for cosmetics packaging, high-end catalog covers)

Anti-Fingerprint Shield: Critical for frequently handled items like restaurant menu covers

Enhanced Readability: Eliminates glare on text-heavy materials (e.g., instructional stickers, safety labels)

Scratch Concealer: Masus minor abrasions better than glossy finishes

Best for: Luxury product boxes, corporate reports, matte sticker labels, medical device packaging

Matte Lamination Process Effect

Gloss Lamination: The Classic Power Player

How It Works: UV-cured polymer creates a liquid-smooth reflective layer

Winning Features:

Color Intensity Booster: Increases CMYK vibrancy by 40% (Pantone certification data)

Water & Grease Barrier: Protects food packaging labels and beverage sleeves

Cost Efficiency: Most affordable protective coating

Shelf Impact: Grabs attention for promotional stickers and retail displays

Best for: Product catalogs, promotional flyers, vinyl stickers, beverage labels

Gloss Lamination Process Effect

The Uncoated Truth: When to Skip Lamination

Strategic Applications for Raw Materials:

Budget-Sensitive Projects: Save 15-30% on unit costs

Eco-Packaging: Recyclability of uncoated kraft paper stickers and corrugated boxes

Temporary Use: Disposable event catalogs, short-term promo stickers

Natural Aesthetic: Artisanal craft packaging

Critical Limitations:

Fades 2.5X faster in UV exposure

Susceptible to oil/water damage

Professional perception downgrade

Uncoated Process Effect

Industry-Specific Coating Guidelines

1. Self-Adhesive Stickers

| Material | Recommended Lamination | Why? |

| Transparent BOPP | Gloss | Enhances clarity & waterproofing |

| Kraft Paper | None | Preserves recyclable properties |

| Metallic Gold Foil | Matte | Prevents fingerprint smudges |

2. Catalog Covers

Sales Catalogs: Gloss (boosts product images)

Premium Lookbooks: Matte (luxury tactile experience)

Technical Manuals: Matte (reduces glare under bright lights)

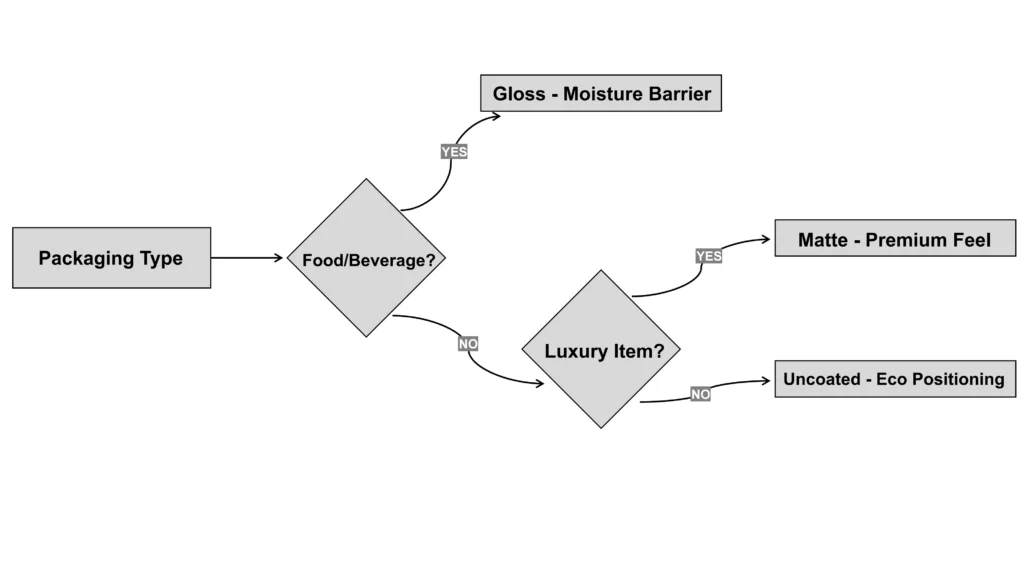

3. Product Packaging

Lamination Selector: Quick Decision Guide